Metal Halide vs HPS Grow Light: Key Differences Revealed

Metal Halide (MH) and High-Pressure Sodium (HPS) are two of the most specialized high-intensity discharge (HID) lamp types designed for plant growth.

But between the two, there are quite a few differences in:

We break all of this down to help you decide the better option based on your distinct needs.

Quick Key Takeaways

How Metal Halides (MH) Grow Light Work

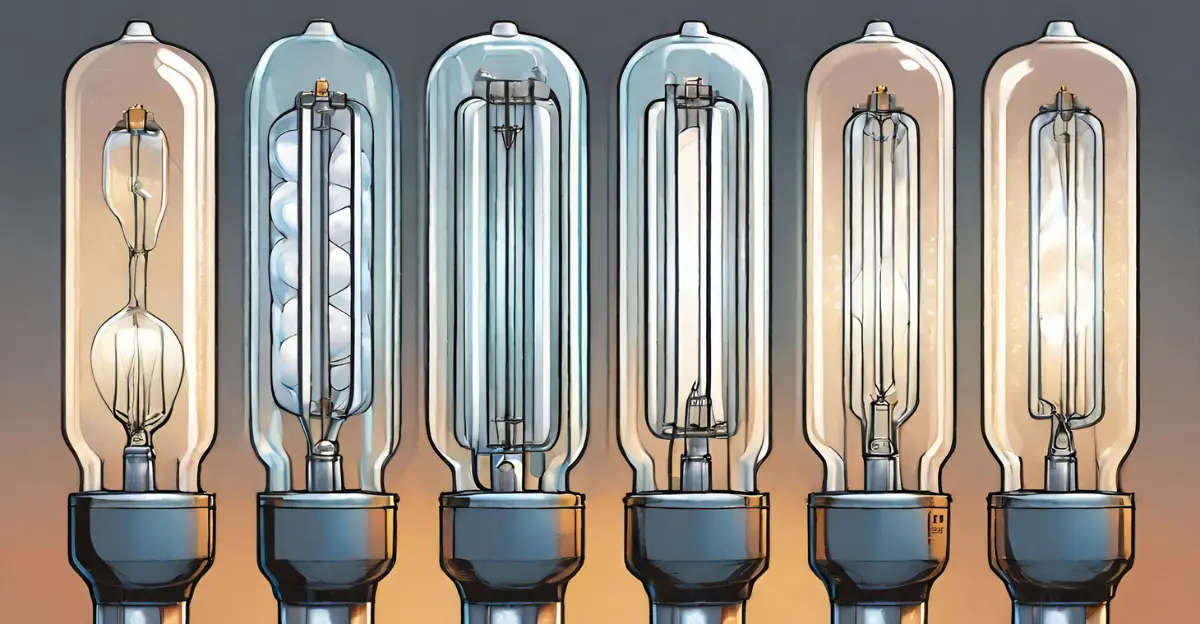

Metal halide (MH) grow lights work by igniting an electric arc inside an arc tube filled with mercury vapor and metal halide salts under high pressure.

This vaporizes the contents, getting them into an excited plasma state that gives off intense light across the spectrum.

Key Components

The key components in an MH system include:

Arc Tube: The glass tube at the heart of the light where the arc occurs. It is filled with carefully chosen metal halide compounds to control the spectrum.

Outer Bulb: Hard glass enclosure to filter out damaging UV rays while letting through useful light.

Ballast: Starts lamp and regulates electrical current. Can be magnetic or electronic. Electronic ballasts are more energy efficient.

Reflector: Redirects light towards plants. Aluminum reflectors, up to 95% reflective.

Pros of Metal Halide Lights

Cons of Metal Halide Lights

How High-Pressure Sodium (HPS) Grow Light Work

High-pressure sodium (HPS) lights operate by generating an electric arc discharge through vaporized sodium and mercury amalgam enclosed in an arc tube under high pressure (up to 2000 psi).

This high-pressure discharge emits a yellow spectrum optimized for fruiting and flowering plants.

Key Components

The key parts of an HPS grow light system are:

Arc tube: Translucent alumina tube containing xenon, sodium-mercury amalgam. Site of the arc discharge (source).

Outer bulb: Borosilicate glass, filtering out damaging UV emission.

Ballast: Provides optimized electrical power to start and operate the lamp. Electronic ballasts are recommended.

Reflector: Aluminium or glass reflector directing light towards plants, up to 95% reflective.

Pros of High-Pressure Sodium Lights

Cons of High-Pressure Sodium Lights

Key Differences

1. Light Spectrum and Quality

| Parameter | Metal Halide | HPS |

|---|---|---|

| Color Temperature | 6500K (white) | 2200K (red/yellow) |

| Light Spectrum | Balanced full spectrum | Enhanced red/orange wavelengths |

| Color Representation | Accurate colors | Red bias distorts some colors |

| Photosynthetic Efficiency | High | High |

Light Spectrum

Metal halide lights have a bright “white” light around 6000k-6500K color temperature, providing a balanced full spectrum from blue to red wavelengths.

This allows for accurate color representation and easier evaluation of plant health.

HPS lights emit a warm reddish light around 1900K-2200K color temperature, with enhanced output in the yellow/red wavelengths from 565-625 nm but less blue light.

This gives a magenta hue that makes color evaluation difficult.

Light Quality

The broad spectrum of metal halides allows for better light absorption and growth across more plant species compared to HPS.

Blue wavelengths in particular drive photosynthesis and impact plant morphology.

The high red/far-red ratio of HPS can cause shade avoidance responses in some plants, resulting in leggy and elongated growth.

This is less of an issue with the fuller spectrum metal halides.

Metal halides render leaf colors and plant features more accurately to the human eye. This helps with tasks like disease detection and flower evaluation. The red bias of HPS can obscure certain plant colors.

Both lamp types have high photon efficiency for photosynthesis and can grow plants successfully. But metal halide’s white light provides a more natural growth environment and workspace.

2. Lifespan and Efficiency

Lifespan

Metal halide lights tend to have a shorter rated duration compared to high-pressure sodium systems. The average lifespan for a metal halide bulb is 10,000 to 15,000 hours.

NOTE: 15,000 hours at 12 hours per day operation equals 1.25 years. However, light output and spectrum start degrading much earlier, with 50% output loss typically occurring at half the rated life. So optimal output is only maintained for 6–12 months.

In contrast, HPS bulbs generally last between 15,000 to 24,000 hours.

NOTE: At the higher end of their lifespan range, HPS bulbs can operate for 4–5 years before replacement. However, output still degrades over time. 90% output remains at the midpoint of life, indicating unsatisfactory levels would typically be reached in 2–3 years.

In essence, real-world average lifespans may end up lower than rated figures in both cases.

Environmental factors like voltage spikes, improper cooling, contamination, and physical mishandling all reduce functional lifetimes.

For example, rapid on-off cycling from digital ballasts stresses bulbs.

An exception is ceramic metal halide systems which offer an enhanced lifespan of 15,000-24,000 hours alongside higher color quality. But these cost more upfront than regular MH or HPS options.

Efficiency

High-pressure sodium systems are more electrically efficient at converting input energy into photosynthetically usable plant light.

Industry data lists efficiency rates of 30-40% for HPS vs 25-35% for most metal halides when new.

3. Heat Output and Management

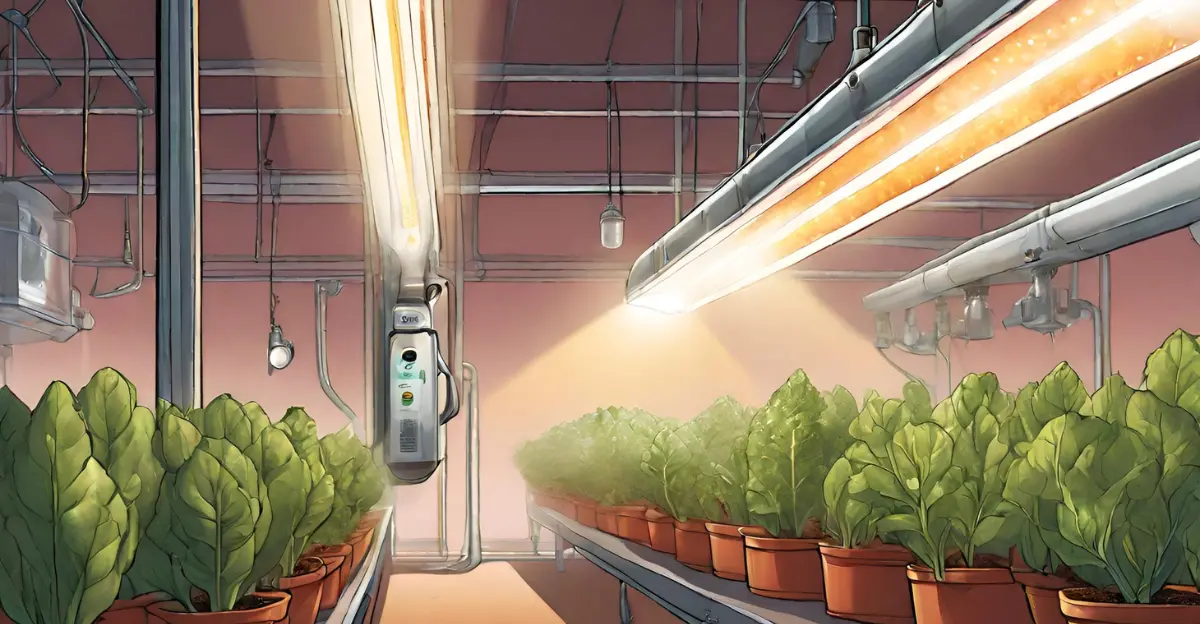

Overall, HPS lights run significantly hotter, producing more infrared radiation that must be offset with cooling systems to avoid dangerous temperatures.

Metal halides generate less thermal output, but still require some monitoring and ambient heating during colder seasons.

According to studies, the infrared heat component causes HPS bulbs to operate around 8 °F hotter than equivalent wattage CMH lamps, and over 10 °F hotter than LEDs.

NOTE: A common 600W high-pressure sodium bulb can reach over 330 °C, temperatures hazardous for fire risk and human contact.

The extra heat load from high-intensity discharge lighting like HPS can benefit plant growth during colder months or environments by better regulating leaf surface temperatures.

However, the same heat can become detrimental during summer months or hot climates, requiring extensive ventilation, air conditioning, or HVAC systems to prevent unsafe temperatures for both human and plant matter.

4. Costs Over Time

Metal halide lights have a lower upfront cost compared to HPS lights. A basic 400W metal halide grow light kit can cost around $120, while a similar HPS kit costs around $200.

However, higher-wattage commercial metal halide fixtures (1000W+) can have similar or higher upfront costs compared to HPS.

For example, 1000W double-ended HPS bulbs range from $35-128, similar to $50-129 for 1000W double-ended metal halide bulbs.

SIDENOTE: High-wattage commercial fixtures would include the costs for ballasts, reflectors, etc. on top of the bulb price.

With more frequent bulb changes, metal halide lighting has higher maintenance costs and labor costs over time.

Metal halide lamps produce around 100 lumens per watt, compared to 85–150 lumens per watt for HPS (source).

So for a similar light output, metal halide consumes less power. The exact % savings depends on the specific fixtures, but 15% is reasonable.

Lower energy usage can offset some higher maintenance costs.

5. Suitability for Plants

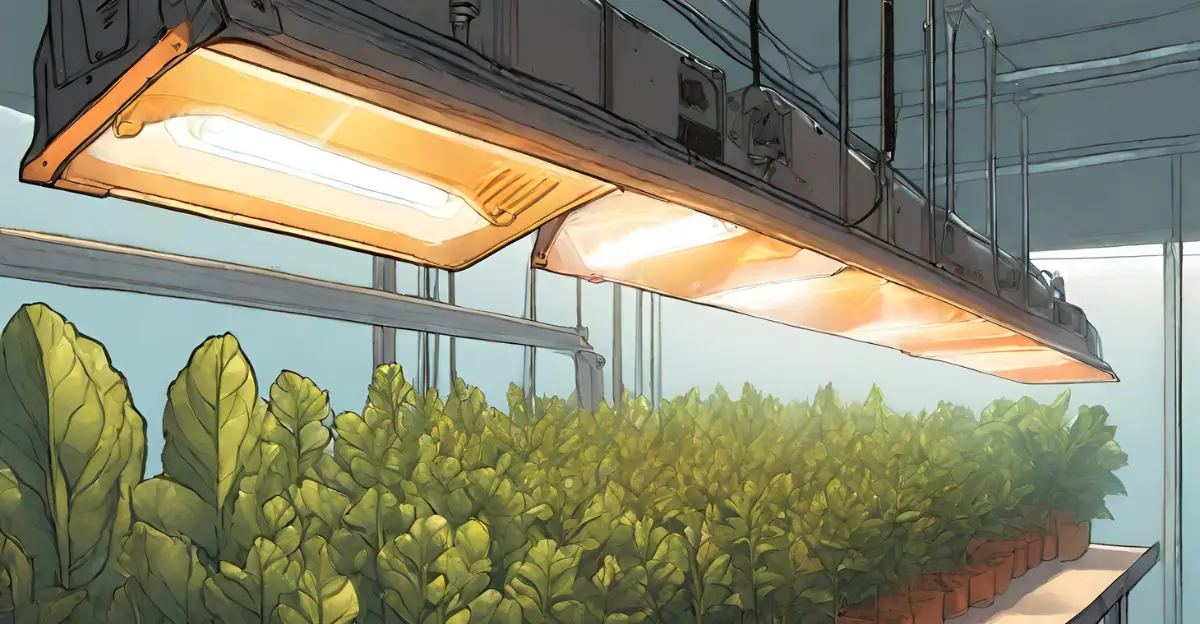

Metal halide lights work very well for leafy greens and herbs. Their color accuracy allows close monitoring of plant health.

And the high blue light content in the MH spectrum drives compact, bushy growth perfect for lettuce, kale, basil, and similar veggies.

MH can carry many plants from seed to harvest, especially “short day” species that don’t require intense red light to flower.

IMPORTANT: Most flowering plants require additional red spectrum light from HPS for optimal flowering and fruiting.

When it comes to flowering, fruiting, or flowering plants like tomatoes, chili peppers, and cannabis, HPS lights excel.

Their red/orange hue triggers prolific blooms, maximizes bud sites, and swells veggies to their juiciest potential.

KEY TAKE HOME: For broader compatibility across both leafy and flowering crops, use MH through the vegetative stage, then switch to HPS for the all-important flowering/fruiting phase. Ceramic metal halide (CMH) lights also offer excellent versatility from start to finish.

Conclusion

And there you have it, my friend – we’ve covered all the nitty-gritty details distinguishing metal halide from high-pressure sodium grow lights.

I know going down the specifications rabbit hole can make an already confusing decision feel even more overwhelming!

But, my aim here was to equip you with objective insights tailored to different gardening contexts.

So rather than just telling you one light is “better”, you now understand key variables like:

Now, I encourage you to reflect on what your indoor garden truly needs – favorite veggies? compact herbs? prolific flowering? – and let the objective pros/cons guide you toward picking the right lights to help your plants thrive to their fullest potential!

FURTHER READING: What Color Light Is Worst for Plant Growth (2024 Updated)

Meet your guide

Dhruvir Zala